What is UV transmission?

What is it and what does it do, a valid question that for once I won’t need to trawl the internet to find the answer, I know it already.

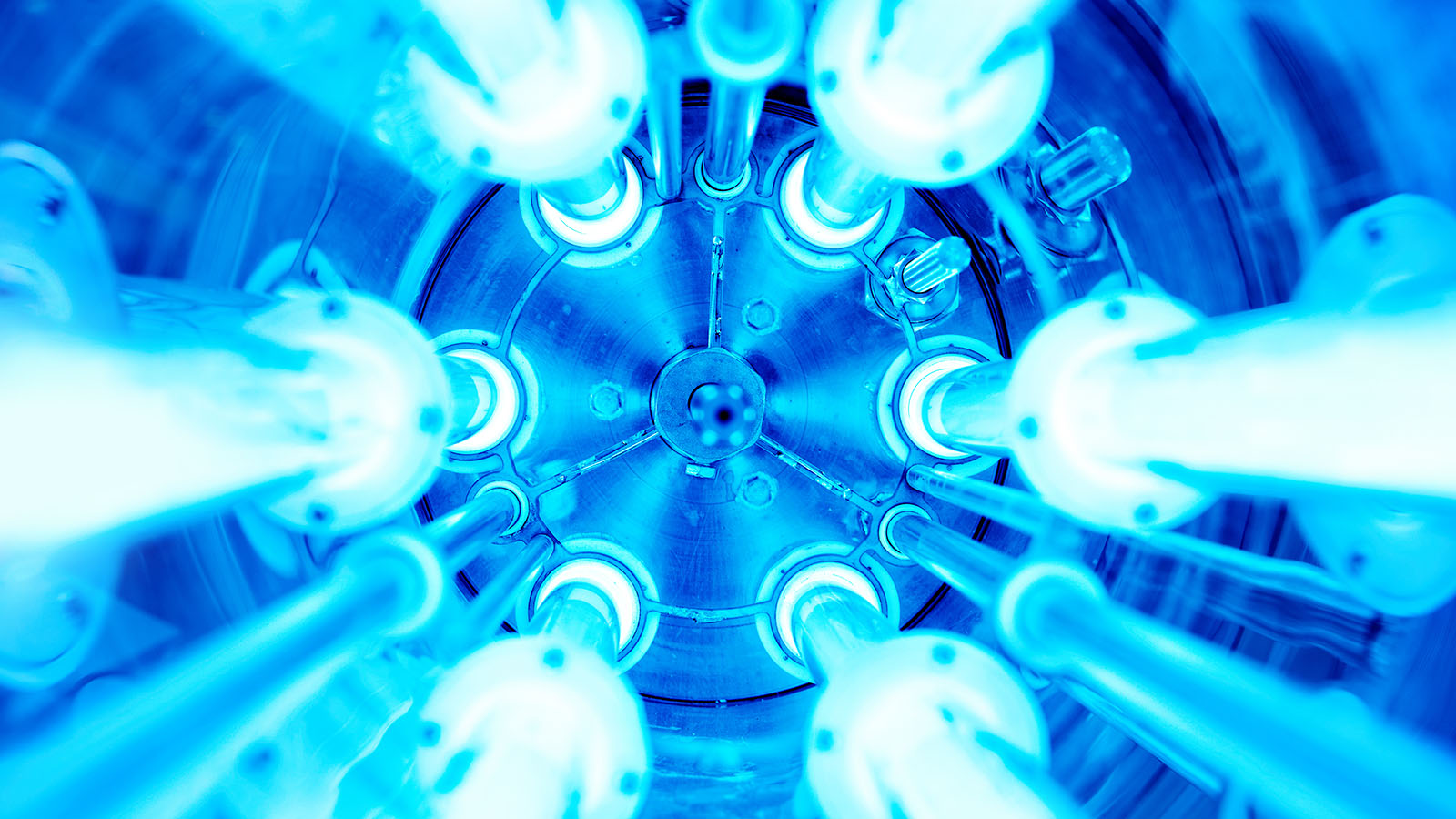

A UV transmission value or T10 is the percentage of UV light will make it from one side to the other when travelling through a 10mm gap. To us, this means we fill a 10mm square vial with the fluid being tested. When the vial is put into the testing unit, one side of it has a UV light emitter, the other a UV receiver. You see where this is going?

As an example, our tap water comes out at around 93-95%. Pretty normal as standards go. But why isn’t tap water 100%, well to make tap water safe to drink it has quite a few chemicals added to it in really small doses. Now, these chemicals deflect or absorb a certain amount of the UV light we fire through it and depending on how concentrated the chemicals are on a particular day, will get a higher or lower T10 reading.

Now say instead of your water coming from the mains supply it comes from a nearby borehole, this water won’t be treated at all and could have anything in, chemicals or germs. Our job is to make that water safe to drink from a germicidal perspective. Once the water passes through a suitable UV unit, there will be no sign of germs, no matter how many there were to begin with. How effective our treatment will be depends on the composition in the water.

One chemical that we come up against all the time and is stupidly efficient at blocking out UV is Iron. UV treating Iron rich water is comparable to firing a bow and arrow at a tank, it’s not going to do very much damage. (The picture in my head may be much better than how this look written down) The only solution to this is to put an Iron filter before the UV unit, there is no other way. There are a few elements that do similar things to Iron, but thankfully they rarely turn up together.

The higher your T10 value the more treatable the source by UV. UV will penetrate much further in water with a high T10 meaning flow through the chamber can be faster or the unit can be more compact and cost less to run. With a low T10, the fluid will still be treatable but a higher power lamp will be used alongside a smaller diameter chamber. This means the water furthest away from the lamp is still pretty close and getting a hefty hit of UV with it.

I cant imagine anyone stumbling across this stuff would find it interesting in the least. My hope is that if you are looking for this question specifically, it might help you get your head round it.